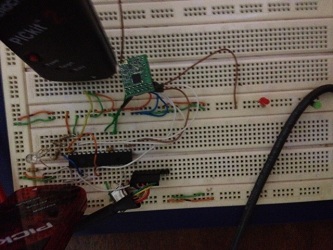

It is time to revisit the RS232 spectrum analyser. Below is an image of some prototyping on a breadboard followed by a soldered working version including an SMA connection. The problem with the previous spectrum analyser was mainly in the computation of the frequency set registers which involved large 9 digit values, a hard feat for an 8-bit microcontroller. This time around a 32-bit microcontroller, the PIC32MX220B032 will be used. This will allow for a maximum clock frequency of 50MHz leaving the radios internal frequency settling time as the only limiting factor to the spectrum analyzer sweep time. The proposed specification for this spectrum analyzer is as follows:

- Bandwidth 260MHz – 960MHz (Realistically about 150MHz according to the input filter of the RFM22B model used)

- 2ms per sample

- Sweep and Discrete measurement modes

- Calibration mode (Calibrates the device with the help of a sweeping signal generator)

- Wireless trace measurement (Two devices needed, one as a base station)

- SD card for onboard storage and buffering

- Connectivity – FTDI cable and rasberrypi GPIO connector header

- Form factor: 1 square inch